The H-beam cutting machine is a high-speed automated cutting equipment specially used for cutting and processing H-beams. The equipment mainly consists of a body, a robotic arm, a control system, a pneumatic source, a hydraulic cylinder, a plasma cutting system, a gas gun, a servo motor, etc. This equipment uses a controller independently developed by our company, with button and touch screen combined control. It uses a servo motor to drive four-coordinate five-axis linkage, automatic hydraulic clamping and feeding, and plasma gas gun cutting. The robotic arm can perform various complex spatial movements. According to user requirements, various cutting functions can be developed to cut any complex irregular shapes on steel, including cutting, mortise, and keyhole in one step. The cut steel is free of deformation and has small errors. All processes are automated, especially suitable for angle steel, channel steel, and I-beam cutting.

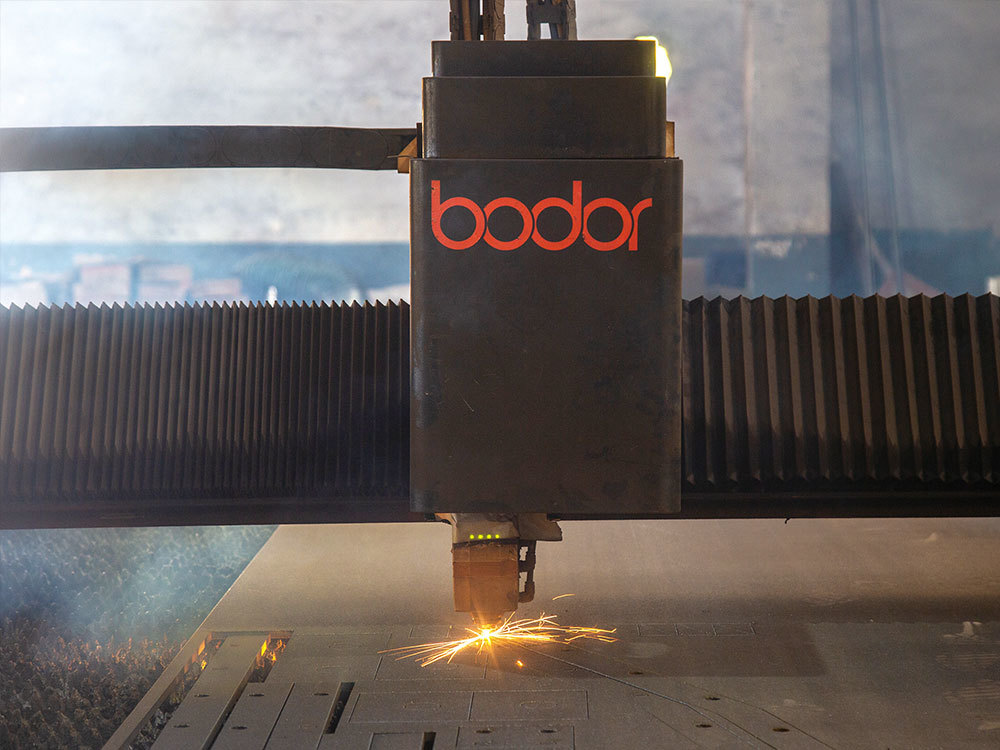

Learn MoreA laser cutting machine uses a laser emitted from a laser source, which is then focused by an optical system into a high-power density laser beam. The laser beam irradiates the surface of the workpiece, causing the workpiece to reach its melting point or boiling point. Simultaneously, a high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, a cut is eventually formed in the material, achieving the purpose of cutting.

Learn MoreSteel structure welding gantry welding is a welding equipment used in the manufacturing and processing of H-beams. Because its shape resembles a gate, it is called gantry welding, also known as H-beam gantry welding or steel structure gantry welding. It is generally used for welding in steel structure workshops.

Learn MoreGround rail type ten-kilowatt laser cutting machine

A kilowatt laser cutting machine uses a laser emitted from a laser, through an optical path system, focused into a high-power density laser beam. The laser beam irradiates the workpiece surface, causing the workpiece to reach its melting point or boiling point, while a high-pressure gas coaxial with the beam blows away the molten or vaporized metal. It can output higher power and complete more working conditions of cutting. As the relative position of the beam and the workpiece moves, a cut is eventually formed in the material, thus achieving the purpose of cutting.

Learn MoreHorizontal hanging board workshop

Steel structure workshops mainly refer to those whose main load-bearing components are made of steel. These include steel columns, steel beams, steel structure foundations, steel trusses (generally, workshops with larger spans now mostly use steel trusses), steel roofing, and note that the walls of steel structures can also use brick walls for enclosure.

Learn More